Project Description

Characteristics of the equipment

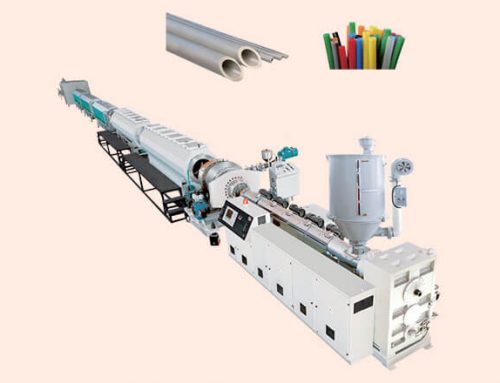

Mainly applying in water-supply pipe, drainage pipe, electrical threading pipe and other area. This extrusion line, equipped with high-efficient & energy-saving twin conical screws extruder, produces PVC pipes four outlet at once by specially designed die mould. Which means high-efficient energy-saving, increasing extrusion speed, economical occupied saving, and low human cost. The non-scrap cutting unit controlled by inverter independently arrangeable cutting speed, compacted by half to ensure long service life and flat and smooth cutting surface without dust trouble. special designed automatic controlled system with good features of easy operation, the whole line linkage, failure alarms, high-efficient control and stable extrusion.

Application

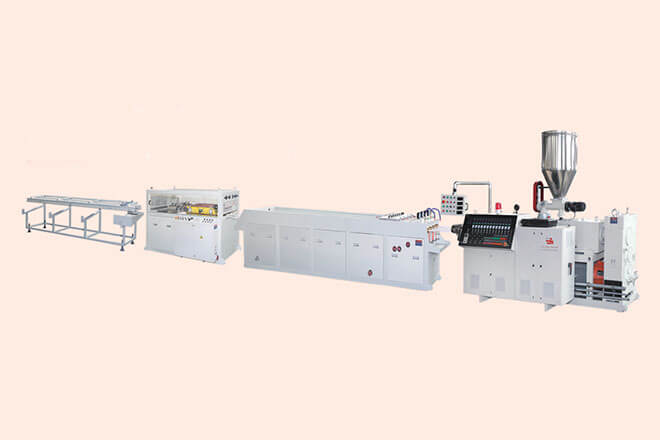

PE/PVC Pipe Extrusion Line

| Pipe diameter | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ110/220 | |||||||||||

| main extruder | 16-63 | 32-110 | 63-200 | 16-32 | 20-63 | 63-110 | 63-110 | 110-250 | 200-400 | 200-400 | 315-630 | 315-630 | 400-1000 | ||

| Die head | Double outlet | Four outlet | Single outlet | Single outlet | Four outlet | Double outlet | Single outlet | Double outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet | Single outlet |

| Down-stream equipment | SGF63 | FGF63 | GF110 | GF200 | FGF63 | SGF63 | GF110 | SGF110 | GF110 | GF250 | GF400 | GF400 | GF630 | GF630 | GF1000 |

| Total power | 91 | 85 | 85 | 86.5 | 91 | 85 | 85 | 136 | 103 | 114 | 131 | 212 | 220 | 270 | 500 |